How 3D Printers Work and What They Can Create

3D printers are machines that can make real objects from digital designs. They work by building shapes layer by layer. People use them to create models, toys, tools, and even art. Learning about 3D printers helps you understand how ideas can turn into things you can touch.

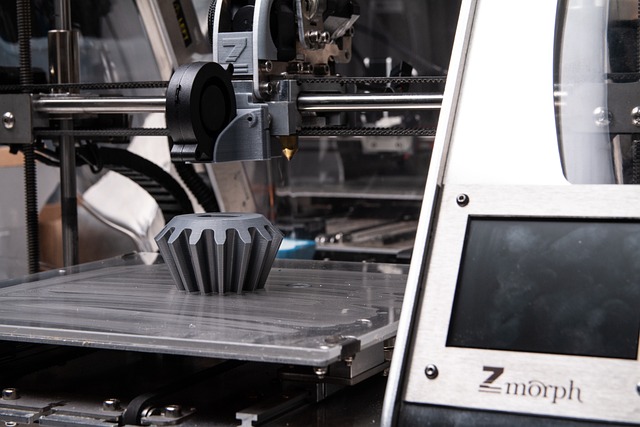

Digital fabrication technology continues to reshape how products are designed, prototyped, and manufactured. From hobbyists creating custom figurines to engineers developing aerospace components, this layer-by-layer construction method offers unprecedented flexibility. The process translates computer-aided designs into tangible objects, bridging the gap between imagination and reality with remarkable precision.

What is 3D Printing Technology?

Three-dimensional printing, also known as additive manufacturing, constructs objects by depositing material in successive layers based on digital models. Unlike traditional subtractive manufacturing that carves away material, this approach builds items from the ground up. The process begins with a digital file, typically created in computer-aided design software or obtained from online repositories. This file gets sliced into thin horizontal layers, which the machine then reproduces physically. Materials range from plastics and resins to metals, ceramics, and even biological substances. The technology has evolved from industrial prototyping tools into accessible devices for educational institutions, small businesses, and home users.

How Do 3D Printers Actually Work?

The printing process varies by technology but follows a common principle. A digital model gets divided into hundreds or thousands of thin cross-sections. The machine reads these instructions and deposits material accordingly, building each layer atop the previous one. Fused deposition modeling, one popular method, melts thermoplastic filament and extrudes it through a heated nozzle that moves along predetermined paths. Stereolithography uses ultraviolet lasers to cure liquid resin into solid forms. Selective laser sintering fuses powder particles together with precision lasers. Each layer bonds to the one below, gradually forming the complete object. Support structures may be added for overhanging features, then removed after completion. The entire process can take minutes for small items or days for large, complex pieces.

Types of 3D Printer Models

Several technologies serve different needs and budgets. Fused deposition modeling machines are the most common for consumers and small businesses, offering affordability and ease of use with plastic filaments. Stereolithography devices produce smoother surfaces and finer details using photopolymer resins, making them popular for jewelry and dental applications. Selective laser sintering handles durable materials like nylon and can create functional parts without support structures. Digital light processing uses projectors to cure entire layers simultaneously, speeding up production. Binder jetting sprays liquid binder onto powder beds, enabling full-color prints and sand casting molds. Metal printers employ laser or electron beam technology to fuse metal powders, serving aerospace and medical industries with high-strength components.

Common Applications of Digital Fabrication

This technology serves countless purposes across sectors. Medical professionals create patient-specific surgical guides, prosthetics, and anatomical models for pre-operative planning. Architects build detailed scale models to visualize designs before construction. Manufacturers produce custom jigs, fixtures, and replacement parts on demand, reducing inventory costs. Educational institutions use these tools to teach engineering, design, and problem-solving through hands-on projects. Artists and designers craft unique sculptures, jewelry, and fashion accessories. The aerospace industry fabricates lightweight components with complex geometries impossible through traditional methods. Automotive companies rapidly prototype new parts, accelerating development cycles. Home users make everything from household organizers to custom toys and hobby items.

Pricing and 3D Printer Options

Costs vary significantly based on technology, build volume, and capabilities. Entry-level fused deposition modeling machines suitable for hobbyists and education typically range from two hundred to one thousand dollars. Mid-range devices offering larger build areas and improved reliability fall between one thousand and five thousand dollars. Professional-grade resin printers for dental or jewelry work cost three thousand to ten thousand dollars. Industrial machines capable of metal printing or large-scale production start around fifty thousand dollars and can exceed several hundred thousand. Material expenses add ongoing costs, with plastic filament averaging twenty to fifty dollars per kilogram and specialty resins costing fifty to two hundred dollars per liter.

| Printer Type | Price Range | Typical Use Cases |

|---|---|---|

| Entry-Level FDM | $200 - $1,000 | Education, hobby projects, basic prototyping |

| Mid-Range FDM | $1,000 - $5,000 | Small business, advanced hobbyists, functional parts |

| Resin Printers | $300 - $10,000 | Jewelry, dental models, high-detail miniatures |

| Industrial SLS/SLA | $15,000 - $100,000 | Manufacturing, engineering, production runs |

| Metal Printers | $50,000 - $500,000+ | Aerospace, medical implants, tooling |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Beyond initial equipment investment, consider software subscriptions, maintenance, and material storage. Some manufacturers offer leasing programs or subscription models that include materials and support. Open-source options provide budget-friendly alternatives with active community support, though they may require more technical knowledge. Evaluating total ownership costs helps determine the most economical choice for specific needs.

Choosing the Right Equipment

Selecting appropriate technology depends on intended applications, budget, and technical expertise. Consider the types of objects you plan to create, required precision levels, and material preferences. Build volume determines maximum object size, while layer resolution affects surface quality and detail. Ease of use matters for beginners, with some machines offering automatic calibration and user-friendly interfaces. Open versus closed ecosystems influence material choices and long-term flexibility. Research community support, available resources, and manufacturer reliability before purchasing. Many makerspaces and libraries offer access to equipment, allowing experimentation before investment.

Digital fabrication continues advancing with faster speeds, expanded material options, and improved accessibility. Multi-material printing enables objects with varying properties within single builds. Continuous printing methods eliminate layer lines for smoother finishes. Integration with artificial intelligence optimizes designs for strength and material efficiency. As costs decrease and capabilities expand, this technology becomes increasingly viable for diverse applications, democratizing manufacturing and empowering innovation across all sectors.