Food Packing Jobs: An Overview of Roles, Work Environments, and Industry Trends

The food packing industry plays a critical role in ensuring products reach consumers safely and efficiently. Workers in this sector handle various tasks, from manual packaging to operating automated machinery in warehouse settings. Understanding the different roles, typical work environments, and evolving industry trends can provide valuable insight into this essential field. This article explores the diverse aspects of food packing positions and how technological advancements are reshaping operations across the industry.

Food packaging employment encompasses a diverse range of positions within the food production and distribution industry. These roles form a crucial component of the supply chain, ensuring products reach consumers safely and efficiently. The sector has experienced steady growth, driven by increasing consumer demand for packaged foods and the expansion of online grocery services.

What Do Food Packaging Companies and Warehouse Operations Involve?

Food packaging companies operate sophisticated facilities where raw ingredients are processed, packaged, and prepared for distribution. These operations typically involve multiple stages, from initial food preparation to final packaging and quality control. Workers may handle various tasks including sorting, weighing, sealing, labeling, and inspecting products. The environment requires strict adherence to food safety regulations and hygiene standards. Many facilities operate around the clock, offering shift work opportunities that can accommodate different schedules. Modern packaging operations increasingly incorporate automated systems alongside manual processes, requiring workers to adapt to technological advancements while maintaining traditional skills.

How Do Warehouse Picking and Packing Processes Function?

Warehouse operations in food distribution centers involve systematic processes for receiving, storing, and dispatching products. Picking involves selecting specific items from inventory based on customer orders or distribution requirements. Workers use handheld scanners and warehouse management systems to locate products efficiently. The packing process requires careful handling of food items, ensuring proper temperature control for perishable goods and secure packaging to prevent damage during transport. These facilities often feature specialized zones for different product types, including frozen, refrigerated, and ambient temperature storage areas. Safety protocols are paramount, with workers required to follow specific procedures for handling equipment and maintaining clean work environments.

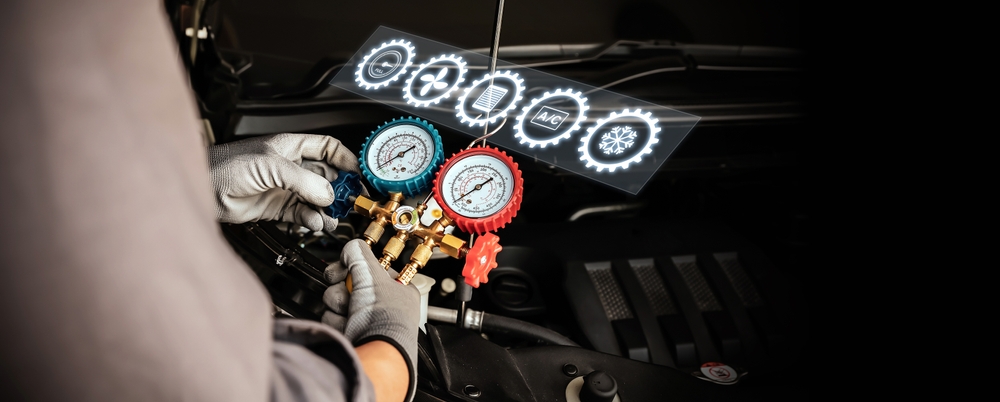

Work Environment Characteristics and Safety Requirements

Food packaging facilities maintain controlled environments with specific temperature and humidity requirements. Workers typically wear protective clothing including hairnets, gloves, and safety shoes. The work environment can be physically demanding, involving standing for extended periods, lifting packages, and repetitive motions. Many facilities provide comprehensive safety training and ongoing education about food handling regulations. The pace of work can vary depending on production schedules and seasonal demand fluctuations. Team collaboration is essential, as most operations require coordination between different departments and shift teams.

Skills Development and Career Progression Opportunities

Entry-level positions in food packaging often require minimal prior experience, making them accessible to various candidates. Workers develop valuable skills including attention to detail, time management, and quality control awareness. Many companies offer internal training programs covering food safety certification, equipment operation, and supervisory skills. Career advancement opportunities may include team leader positions, quality assurance roles, or specialized technical positions. The experience gained in food packaging can transfer to other manufacturing and logistics sectors, providing a foundation for broader career development.

Industry Trends and Employment Outlook

The food packaging industry continues evolving with technological innovations and changing consumer preferences. Automation has transformed many operations, though human oversight remains essential for quality control and complex tasks. Sustainability initiatives have introduced new packaging materials and processes, creating opportunities for workers to learn environmentally conscious practices. The growth of e-commerce and meal delivery services has increased demand for specialized packaging solutions. Brexit and supply chain disruptions have highlighted the importance of domestic food processing capabilities, potentially supporting employment growth in the UK food packaging sector. Companies increasingly value workers who can adapt to new technologies while maintaining high safety and quality standards.